I have beamed on the dummy warp. I have wound the handspun warp bouts. Now it is time  to tie on.

to tie on.

THE SETUP

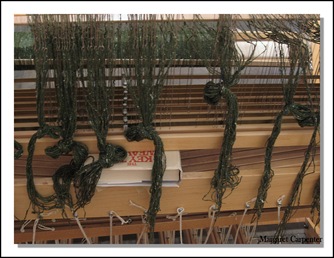

Here is a view from the side of the loom that shows the general setup.

The view is from the side at the back of the loom. I have already tied on about three quarters of the handspun warp.

At the left you can see the first set of lease sticks and the beamed-on dark red dummy warp coming through it. The instrument to the left with the “points” is the raddle. At the top of the photo, still looking at the dummy warp, you see a group of dummy warp threads that are waiting to be cut so that I can tie onto them. In front of those loops, in the second set of lease sticks, are the ends of the green hand spun.

Below that all the rest of the dummy warp ends are tied to the handspun warp.

Here is another view, this time from the back of the loom. Looking at the second bout from the left shows that the ends have been pulled out (but not from the lease sticks) and pulled  over the front set of lease sticks. This is the bout I am working with and it is pulled up and out because it is easier for me to pull the ends from the lease sticks when they are horizontal, than when they are hanging down towards the floor.

over the front set of lease sticks. This is the bout I am working with and it is pulled up and out because it is easier for me to pull the ends from the lease sticks when they are horizontal, than when they are hanging down towards the floor.

Also visible is that the bouts are coming from the front of the loom, where they hang over the front beam. The bout I am working from is hanging free over the front beam to give it just a little bit of tension, so making it easier to pull threads out from the cross. The others rest lightly on the loom bench.

After I tie a group of ends, instead of leaving them flop around and tangle with each other, I make a loose slip knot to keep them together. The slip knots are better seen in the first photograph above. They are in front of the second set of lease sticks on the right.

Here is a detail from the back of the loom of the untied warp ends. The bout on the left has not been started. It still has the two ties (red) which enclose the top and bottom of the cross as it comes off the warping cross. And it still has the counting cross tie (yellow).

Here is a detail from the back of the loom of the untied warp ends. The bout on the left has not been started. It still has the two ties (red) which enclose the top and bottom of the cross as it comes off the warping cross. And it still has the counting cross tie (yellow).

The next bout is the bout I am working on. There were three groups counted off by the yellow tie and only one remains. I undo them one at a time as I work to keep things neat and easy to work with. There is one errant thread, directly to the right. It’s not really errant at all. It is the last end in the second group of that bout and it is waiting to be tied to the appropriate end of the dummy warp.

KNOTS

I did not want to use a weaver’s knot to tie the knots. I have been taught to make them. I have taught myself to make them. They make a very neat know which passes easily through the heddles. I understand that they are also a very quick knot to make…………once you know how.

I do not routinely tie on warps. There are many weavers who do. If I did routinely tie on warps I would probably both with the learning curve for the weaver’s knot. Learning that knot would make a difference. But I decided that wasn’t worth it for the few times I do this.

So when I started tying I used a granny knot, the first part of which was double wrapped like a surgeon’s knot. But it didn’t always hold. Each time I make the knot I test it by pulling the long ends (the ends that attach to the bout) hard. I frequently had to retie because the smaller red end would pull free. When I got to one end that I had to retie something like seven times I gave up and turned to a square knot. Once in a while, one of those would slip and I would have to retie, but not very often.

The slippage occurs because I am tying a relatively thick thread to a relatively fine thread. The fine red thread wants to pull out from the heavier green thread. This seems most likely to happen when the green thread at that point is a little softer with less twist. Not so much twist went into that part because the fiber at that point was just a little thicker than the fiber on either side of it. A granny knot seems to deal with this issue better than a square knot. But it is not foolproof!

I tried the granny knot first because that is easier for me to manipulate. But by the time I got to the point where I am now, the square knot was almost as easy to tie as the granny.

WARP END LENGTHS

One thing worries me. It worried me with the previous two handspun warps, but neither time did the worry bear fruit. Still I worry again. There is no way I can tie these ends together and come up with all the lengths of warp the same length. I just can’t do it! In fact, this is one of the advantages of beaming back to front. Instead of tying on to the back beam which results in uneven lengths, you put the rod through loops. A quick pull or two from the first choke tie and everything is even.

Are these length differences going to make for difficult weaving? They didn’t on my other two projects. My guess is that two things are going on that prevent this from being a problem. When I throw my first shots to get the warps properly separated for good weaving, there are always ends which bunch up, ends which are clearly longer than they other ends. Evening these out seems to be one of the jobs of those first shots.

The second issue is that this is a short warp, so any minor differences that might be left after those opening shots is not going to have a chance to become a major difference.

WHY BOTHER?

There is one blogging weaver who weaves a great deal with his own handspun and does not go through all this. Dave simply warps up his loom as he would for any commercial warp. He doesn’t worry about the waste. Do check out his blog, for he weaves lovely scarves from his own handspun.

I can certainly understand Dave’s not bothering with a dummy warp. What I am doing is a lot of extra (and tedious!) work. On the other hand, this is a rather wide warp I am putting on. I wanted to make the warp as wide as I could. This meant doing everything I could to conserve yarn.

Related Post: Preparing the Warp Bouts for the Loom

“Tying the Handspun to the Dummy Warp” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 19, 2009. ©2009 Margaret Carpenter aka Peg in South Carolina