Posted by Peg in South Carolina

PLEASED BUT A FEW ISSUES ANYWAY

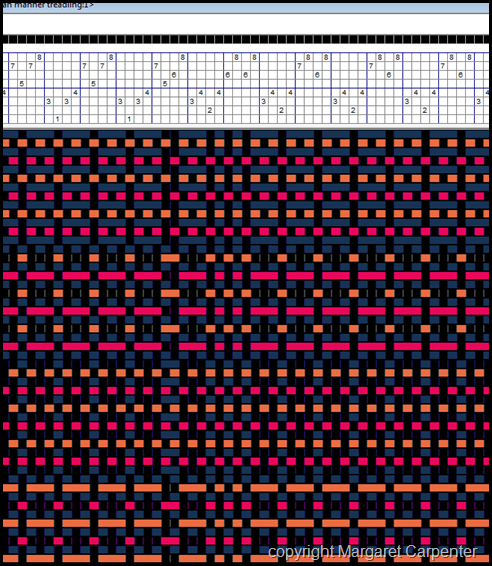

I am very pleased with how the warp is handling during this test weaving. I still have some problems with clean sheds. The problem is clearly visible in the mirror I use and it is easiily resolved by simply strumming with my hand the top part of the warp. Since I am sampling, I am fairly easily prone to treadling errors, but once I settle on the treadling structure, that problem should begin to clear itself up.

I am also having problems with the selvedges. The selvedges themselves are fine. The problem is that weft threads tend to get caught there and form loops—sometimes long loops. I am using 3 shuttles and that is a normal problem. I have not been particularly concerned with it during the test weave, but when I start the real stuff, I will have to become concerned.

Related to that problem is little loops of weft sometimes appearing somewhere across the warp. They are probably also on the underside. I should be able to resolve that by tightening the tension just a bit on my end feed shuttles.

I am ready to start sampling with the yarns I dyed for this project. No more stash yarns! I have a good idea of what I want to do, but I will have to test it. I was getting so excited.

Yes, the tense of the verb is correct – “I WAS getting so excited.”

THE “BIGGIE”

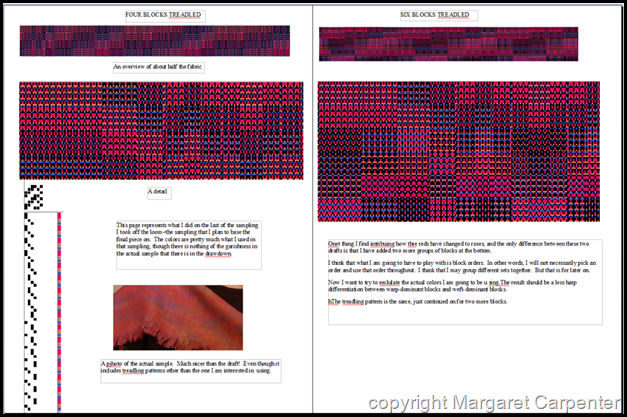

I have been watching a nasty line develop along the length of the warp in one spot on the left side. The detail below shows it quite distinctly.

I finally checked it out. As I suspected, a threading error.

A SOLUTION

I figured that I could insert the 4 necessary repair heddles on the correct shafts. I could lengthen the 4 yarns by tying on more length to each of them. Then, after threading and sleying, I could put a pin in the weaving and wind the yarns around the pin to tension them. Or I could just weight them off the front of the loom.

Doing this was going to be a bear. I decided to wait until this evening when my husband was home. That way he could hold each shaft up for me while I attached the repair heddles.

But…

ANOTHER SOLUTION

There is at least one more similar threading error on the left side. So I really think re-threading the left side is in order. Also, the sett 0f 60 epi means that the heddles are pretty close together and in the problem area I would have 4 empty heddles taking up the same amount of space that the 4 repair heddles would take up. This, it seems to me, could affect the cleanness of the sheds. Sigh

So, right how this is my plan.

Cut off the warp at the fell, but only on the left side, beginning with the first threading error. To keep the warp rod level and steady, I will insert a piece of wood for it to rest on. I will pool the ends out of the reed and out of the heddles and re-thread that side. First, of course, I have to find in my threading draft where that starts.

I will re-thread, praying that I make no new and surprising threading errors. Resley. Then cut the rest of the warp off at the fell, remove the weaving and tie on the warp again.

Hoping all that goes uneventfully, I will then test-weave one more sample with stash yarns; then start using the real yarns………..

WHO IS IN CHARGE HERE?

Am I getting discouraged? Well, yes. At least at times I feel discouraged. But really, a better word to describe my feelings right now is a kind of calmness. Actually almost a sense of numbness. I no longer care about getting this finished, at least in any particular time frame. I just kind of feel like I am in some kind of time warp (pun?) where the piece is in control. It is going to be ready to weaving only when it is ready.

Related Posts:

Test Weaving the Warp

Finished Sleying? Well, No

“Crackle Threading Issues Emerge” was written by Margaret Carpenter for Talking about Weaving and was originally posted on August 14, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina