Posted by Peg in South Carolina

“Overshot Treadling Extended” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 26, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

“Overshot Treadling Extended” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 26, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

Note on colors: These are not the real warp colors. The real colors are reddish brown and khaki green. Whew! The point of these photos is not to get accurate colors…..

I had read somewhere about a weaver putting a second raddle at the top of her/his loom before beaming the warp on.* I thought this was an excellent idea and determined to try it out myself on my next warp. So here it is.

First, a picture of the back of the loom as I was in the process of the first part of raddling.

This first view is from the back of the loom.

On the back my 4 dents per inch home-made nail raddle is visible. A very amateur job of nailing, but it works. At the top of the loom on the castle is a Harrisville raddle with 1 dent per inch divisions.

The newspaper keeps the unraddled warp ends from falling into the raddle spaces and getting tangled. The little table is for my back rod to rest on until I am ready to attach it to the back beam. Two little pieces of tape are visible holding it onto the table. That is what I do when I leave the loom to go do other things. That helps keep the rod from being knocked who knows where.

Viewed straight on from behind:

The next view is from the front of the loom. When I wound the warps, I put each bout in an individual sandwich baggie. Then I grouped several bouts together in larger plastic bags. Doing this has resulted in a warp I can handle without threads getting all tangled up. Kitty is wondering if all this is really worth it.

I am now ready to beam on except for removing the choke ties near the castle. Since my bouts were slightly less than one inch wide, the choke ties have no relation to the inch divisions of that raddle and would only choke everything up as they tried to pass through the raddle.

This process has already revealed to me a problem which I corrected. One of the warp ends was very very loose and when I followed it through to the lease sticks I discovered that it had somehow gotten tangled and there would be no way those ends could pass through the lease sticks. I fixed it.

Related Post: Another Raddling Tip

*My apologies to the person whose idea this was. I have no memory of who gave me the idea, or even whether the idea came from a weaving blog or from a weaving list. If anyone would like to share the name of this weaver with me, I would be most grateful.

“Using Two Raddles” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 24, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

This is only one tie-up of several possibilities. For now, this is the tie-up I will be using.

Related Posts:

6-Shaft Crackle Threading Treadled Overshot

4-Shaft Crackle 01.05.10

“8-Shaft Overshot Treadling” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 24, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

If you haven’t seen Tien’s wedding dress, do go and look at it. It is stunning. But read all the blog posts about it as well. Here is the blog post with the photos.

But there is much more in Tien’s blog than the post with the photos of her garment. These other blog posts contain the story of all the ups and downs that occur in creating a project of this magnitude. But even more important for me, these posts contain the story of an amazing collaborative effort.

The effort involves scores of people. People who gave her helpful advice and encouragement in the comments on her blog. People who lent her tools. People who gave her things. People who taught her. I find it an amazing story.

Years ago when I lived in Georgia and was a member of the Chattahoochee Handweavers Guild, two members of that guild collaborated on a magnificent piece which won a major award at Convergence that year. One was a gifted and experienced weaver. And one was a weaver and dressmaker.

They told the story of their collaboration at a guild meeting. I was absolutely entranced. This was not the story of the lonely weaver working by herself at her loom or at her sewing machine. Of course there was this work, and much of it. Nor was this the story of a weaver collaborating with a client on a piece. This was a collaboration between two weavers, each of whom brought her own set of skills to the challenge, and each of whom challenged the other from the beginning of the project to its end.

“Weaving and Collaboration” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 22, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

“Summary of 6-Shaft Tie-up Combinations” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 22, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

“Fourth Treadling” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 17, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

“Third Treadling” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 16, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

WHAT DOES “SHIP IT” MEAN?

“Ship It” is a phrase used by Seth Godin in his latest book Linchpin: Are You Indispensable?* Basically this means that with any project, time is going to run out, money is going to run out, it’s time to move it on. Why? Because, according to Godin, “…the projects we do are never really finished…….” (page 103)

Most of us weavers would probably interpret this to mean, send the piece, imperfect as it is, to the show, give it to the person. It’s not perfect, but get it out of here to where it belongs. Only then is it finished.

But I am interpreting Godin’s explanation of shipping as including something more than, say, just getting a piece to a show. Indeed, I find myself right now at what I would call a “ship it” moment in my own weaving. And the warp isn’t even on the loom yet!

MY “SHIP IT” MOMENT(S)

I dyed the last of the warp yarn. I clearly did not get the calculations correct because it does not match the warp yarn I was trying to match. It is definitely brown, not a reddish brown.

Moment #1. My first thought was to wind another 1600 yards of white 60/2 silk and dye it, this time, getting the right color. But my next thought was, is this simply perfectionism for perfectionism’s sake? Seriously, is this really going to matter in the final outcome? I decided not. I was done with the warp dyeing. I needed to move on.

A quote from Godin’s book:

Laugh at perfection. It’s boring and keeps you from being done. (page 130)

I hadn’t read Linchpin at this point, but when I got to this quote, I smiled.

Moment #2. Still into perfection, however, I dreamed up the following plan. I thought I would wind the rest of the warp with this incorrectly dyed yarn. But I would put it on separate lease sticks and end rods. Then I would insert these new brown warp bouts somewhere into the warp bouts I have already made. I would insert them in a place where they would serve best as a design element.

This seemed a pretty good idea. Doable. And who knows, it might turn out to be better than actually having gotten the color right in the long run.

But this sort of thing could go on forever and I might never get the warp on the loom. This warp will never be perfect; the completed weaving will certainly not be perfect. It is time to stop worrying about the warp and get on with it. It has cost me too much in time as it is.

I close with one of my favorite quotation from the book:

Accept that everything is a draft. It helps to get it

done. (page 128)

*You can also find Seth Godin at his blog, here.

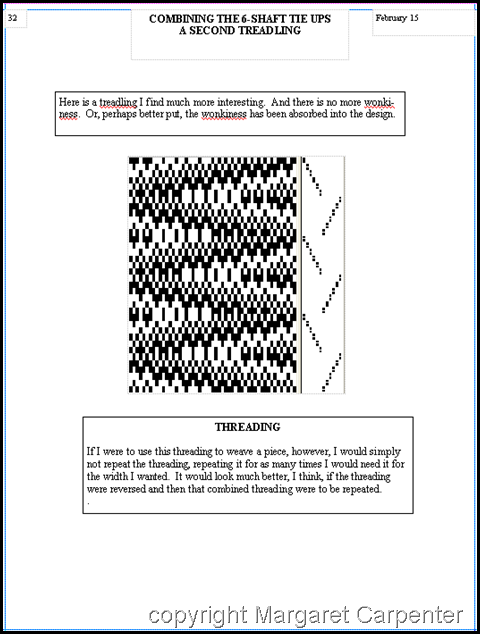

“A New Treadling” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 15, 2010. ©2010 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

To reverse the tie-ups I simply used tie-up #2 first and tie-up #1 second.

Note spell check at work……….

“Reversing the Two Tie-Ups” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 11, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

I was determined to dye the rest of the warp yarn I so desperately needed. To dye it this week. An impossible week. I finally decided on today—Wednesday.

I got up at 7—my usual time—but I cut my morning yoga very short. I also did not do anything with my hair…… I was dressed, breakfasted, and at the dyeing by 8:00.

To make life easier this morning, I had done a lot of preparation the night before. The most time-consuming was to make the four individual dye solutions so that they would be ready to pour in the dye pots when the time came. I also got all my equipment and supplies out, put water in the stock pots that would hold the dyeing jars, and put the skeins of yarn in a solution of hot water and Synthrapol to soak overnight.

To make life easier this morning, I had done a lot of preparation the night before. The most time-consuming was to make the four individual dye solutions so that they would be ready to pour in the dye pots when the time came. I also got all my equipment and supplies out, put water in the stock pots that would hold the dyeing jars, and put the skeins of yarn in a solution of hot water and Synthrapol to soak overnight.

I was finished a little before 11:00. I could get on with the rest of my life.

One odd thing I noticed. The yarn I was dyeing the deep reddish-greenish color for the warp looked gray in the dye pot for at least 30 minutes. I worried a bit. I needn’t have. Sometime later it was the color it was supposed to be. But this was a curious phenomenon.

Related Post: My Warping Board Eats Yarn

“Rising Early to Dye” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 10, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

After yesterday’s post, my next task was to check out the two individual tie-ups with the combined tie-up to see if I had made an error. I copied each of the tie-ups onto a page in my e-journal to make it easier to compare them. I discovered that I had not made an error.

No error. Soooo…..what to do next?

“Comparing the 6-Shaft Tie-Ups” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 10, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

Related Post: Combining Tie-Ups in 6-Shaft Crackle

“Combining 6-Shaft Tie-Ups Continued” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 8, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

I was curious as to what would happen if I were to combine the two tie-ups for 6-shaft crackle into one draft. And this page from my current crackle sketchbook shows the result.

One thing I find interesting is how the design changes a bit in the blocks on the right. I’m not sure right now how to account for that.

Related Posts:

A New Tie-up for 6-Shaft Crackle

6-Shaft Crackle Threading Treadled Overshot

“Combining Tie-ups in 6-Shaft Crackle” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 5, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

At least it sure feels like it does. I had run out of yarn and so dyed some more. I figured roughly how much more I needed and dyed the yarn.

I should never never never trust calculations I make in my head.

I had calculated roughly 500 more yards. Using my head.

This time I decided to use a calculator. Using a calculator shows I need a minimum of 935 more yards. That means I probably needed to have dyed roughly 1800 yards. Not 500 yards…..

So now I have to cone off another white skein, then from the cone wind a skein for dyeing and then dye.

I do have some more colors I want to dye for weft, so I will make the calculations for that and dye them at the same time.

I am looking for red-violet weft yarns that are brighter than those that I have dyed. To the left is an example of the brightest. Deep and rich, which I like, but I also would like some brighter versions. Not psychedelic. Just brighter.

I am looking for red-violet weft yarns that are brighter than those that I have dyed. To the left is an example of the brightest. Deep and rich, which I like, but I also would like some brighter versions. Not psychedelic. Just brighter.

That might finish my dyeing for this piece. Unless I decide to use tabby. Then more dyeing.

Next week is a terrible time to find a block of time to dye in. I do NOT want to wait another week before I can start getting this warp on the loom!

Jeezzzz……………………..

Related Post: I Really Ought Not to be a Dyer

“My Warping Board Eats Yarn” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 5, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

Instead of the overshot treadlings I have been working with, here, once again, is the tromp-as-writ. I adore it in the 6-shaft crackle.

Related Post: Tromp as Writ

“6-Shaft Crackle Tromp as Writ” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 1, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

I have just enabled comment moderation. On Saturday, and again today, I received dozens of anonymous comments in some oriental language. I have seen this happen on one other (textile but not weaving) blog.

Posted by Peg in South Carolina

Related Post: Blocks as the Design Feature

“More on Blocks in 6-Shaft Crackle” was written by Margaret Carpenter for Talking about Weaving and was originally posted on Febuary 2, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

When I wind a bout on the warping board, I put in a counting yarn at the cross. With this particular warp I count off 20, 20 and 12 because there are 52 ends in a bout.

More than halfway through, I realized how silly this is. I don’t need three groups in each bout; I only need two. How much more sense it would be to wind 24 in one group and 28 in the other!

Or would it? When I warp two ends at a time, it has been my habit to wind 20 in a segment of a bout, with the last segment generally being a smaller number, say 8 or 16. Developing habits is very important as they help reduce errors.

So I think what I could have done was to count off 20 and then 32. Then, the problem is that I might more easily make a mistake with 32 than with 20, if only for the reason that I am winding more ends before I stop. But it would certainly be more efficient to have to twist the tie cross only once and then tie it.

As for tying off 52 without a counting cross. No. I would absolutely have to double-check each bout and that would use up the time I would have saved by getting rid of the counting cross.

A GLITCH IN WARP WINDING

As for winding the warp, I have been momentarily derailed. I did not have enough of one of the colors. Since I didn’t want to dye just one skein, I have been working out more dye colors and winding more skeins. It looks like this time i might be able to dye seven skeins in one go. They are small skeins………..

“The Counting Cross” was written by Margaret Carpenter for Talking about Weaving and was originally posted on February 1, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.

Posted by Peg in South Carolina

For any just stopping by for the first time, this is part of my crackle-draft-a-day project and the images for these posts are pages from my e-sketchbook, which I keep in Microsoft Publisher.

Go here to learn more about this project.

Related Post: Alternating Treadles on 6-Shaft Crackle

“Blocks as the Design Feature” was written by Margaret Carpenter for Talking about Weaving and was originally posted on Febuary 1, 2010. ©2009 Margaret Carpenter aka Peg in South Carolina.